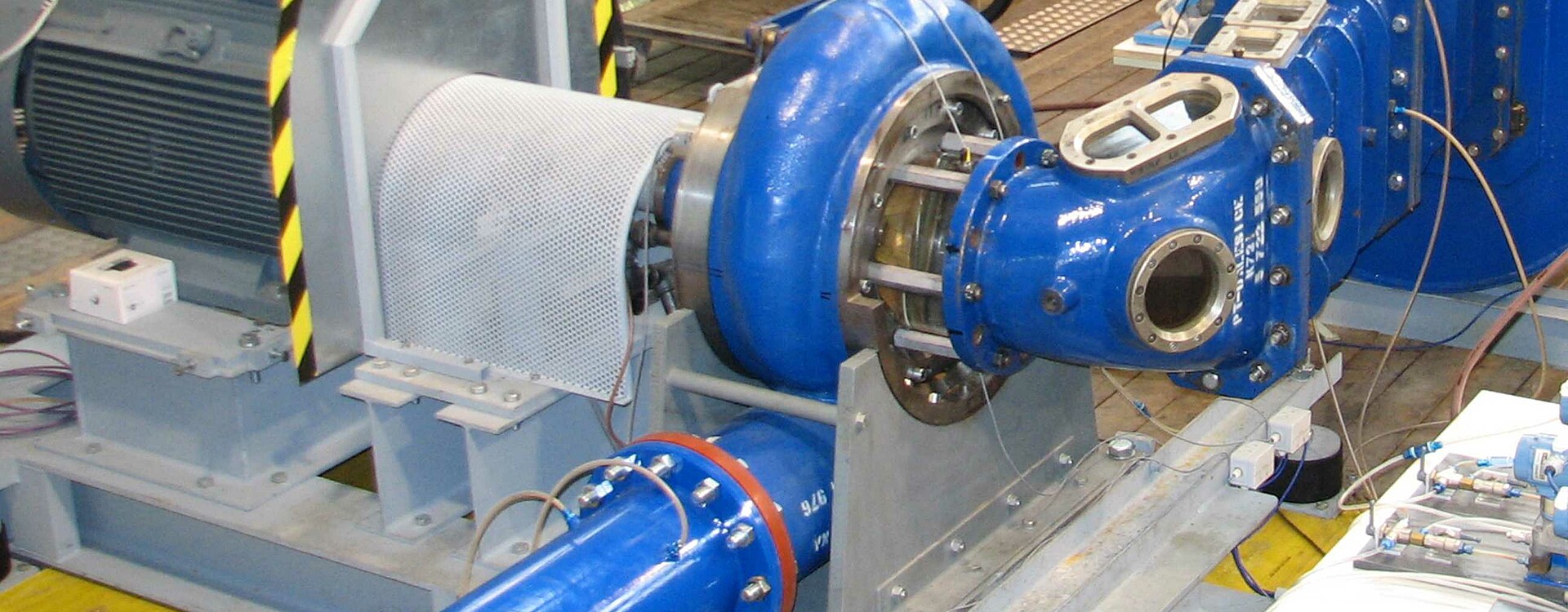

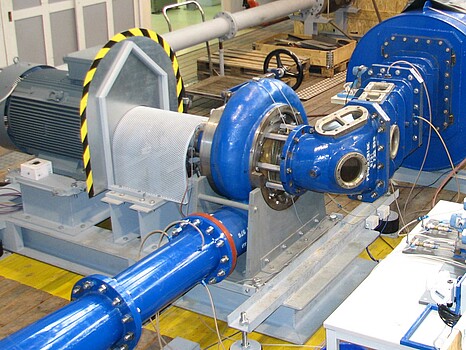

The pump as a turbine: Application in industrial processes

As an energy-generating accompanying measure reducing operating costs in industrial plants or in micro and small hydropower plants, the use of a pump as a turbine (PaT) allows previously unnoticed potentials for energy generation to be profitably realised.

Usually, centrifugal pumps running backwards are used for power generation in such applications: When water flows backwards through a pump, the rotational direction of the impeller reverses and the pumps become turbines.

When does the use of pumps as turbines make sense?

Pumps are particularly suitable as turbines when the investment costs for conventional turbines are too high, making energy generation uneconomical. As a series product, a pump causes significantly lower investment costs and thus compensates for the possibly lower efficiency compared to a "real" turbine. A profitable use of a pump as a turbine can already be realized from head of 2 metres, a volume flow rate of 10 l/s and even with discontinuous inflow.

Efficiency comparison

Depending on the design, the hydraulic efficiency of turbines is around 95 % and a reversed pump achieves an efficiency of up to ~85 %. If a constant volume flow cannot be expected, the consideration of the partial load capability is of essential importance in order to maximise the achievable annual yield. Due to the lack of a guide vane between the pump and the turbine, a good partial load behaviour of the pump can only be achieved by dividing the total volume flow into several units, which can be switched on and off as required.

Fields of application

In the course of efforts to massively increase the share of renewable energy sources, potentials that have been neglected to date are recognized and realized with innovative approaches. In addition to conventional hydropower, existing industrial processes are increasingly being used to recover energy. The large-scale use of PaT units in pumped storage power plants is clear proof of their successful and profitable operation. This results in a wide range of applications and the associated use of media:

Media:

- Drinking water

- Residual and waste water

- Popular media in industry:

- Stock suspensions in the pulp and paper industry

- Oil / oil mixtures

- Cooling circuits

- Gas scrubbing plants

- and much more

Areas of application:

- Small hydropower

- Drinking water networks

- Pressure difference reduction between high and low tanks

- Pressure control in closed systems

- Pressure reduction of slopes

- Residual water use in hydropower plants

- Snowmaking equipment for slopes

- Industrial plants as a replacement for throttling devices, e.g. in cooling circuits

- Wastewater treatment plants

- Pipelines

and much more.

The advantages of pumps compared to turbines

Pumps have low life cycle costs, due to the very low purchase costs for a pump at an equally remarkable efficiency.

PaT units usually pay for themselves within a few years. Investment costs are low and in most cases a feed-in tariff or support for renewable energies can be expected and thus the economic attractiveness of such a plant is further increased.

Due to the standardisation of pumps, an adaptation to a fluctuating water supply can be made by dividing the total volume into several units of the same or different sizes. This improves the partial load behaviour of the plant, since, unlike a turbine, there are no adjustable control devices.

In an ideal case, an existing pump is also used temporarily to generate electricity and thus an existing infrastructure achieves a profitable expansion of use through adaptations, e.g. for snow-making systems for ski slopes, even when multi-stage pumps are used.

Conclusion

The use of pumps as turbines is convincing due to the significantly lower purchase costs, whereby each application should be critically analysed on the basis of the achievable average annual output compared to the life cycle costs, i.e. procurement costs, follow-up costs as well as triggered costs/savings in other areas of the company. With the help of the know-how of experts covering both the "pump" and "turbine" fields, unnoticed potentials for energy generation and for increasing the energy efficiency of plants are realised – strengthening competitiveness and protecting the environment.

You might also be interested in this:

Energy Efficient Pump Systems

Optimisation potentials throug speed control

Stay up to date

Subscribe to our newsletter and stay up to date on our activities, continuing education and conferences.

We are your independent expert for:

- Analysis, design and optimisation of hydraulic machines, components and complete systems

- Acceptance tests and model tests according to IEC 60193, ISO 9906, IEC 60534, IEC 62006

- Comparison of experimental data with numerical simulation (3D-CFD)

- On-site measurements according to IEC 60041 and IEC 62006

- Plant, operation and life cycle tests

- Endurance test

- Water hammer and pressure surge as well as transient conditions of fluid and gas flows

- Fluid-structure interaction

We look forward to your enquiry!

Our experts for your fluid technology issues for pumps, turbines and systems:

Helmut Jaberg

O.Univ.-Prof. em. Dipl.-Ing. Dr.techn.

CEO (Managing Partner)