Development of a new runner

for a Francis turbine with heavy erosion phenomena

Hydropower plants that are operated in alpine regions often suffer from erosive wear and tear. Particularly if the catchment area is located in valleys that are still glaciated, maintenance intervals of only a few years are often to be expected. We have recently completed the development of new Francis replacement runners for one such power station. The power station in question has two vertical Francis turbines, each with an output of approx. 14 MW. The operator decided in favour of a new development primarily because massive erosion damage to the runner blades and the outer ring (see pictures below) meant that the runners urgently needed to be replaced again.

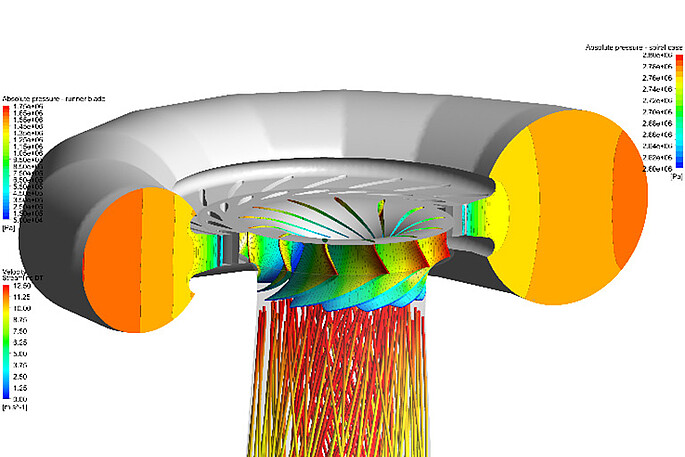

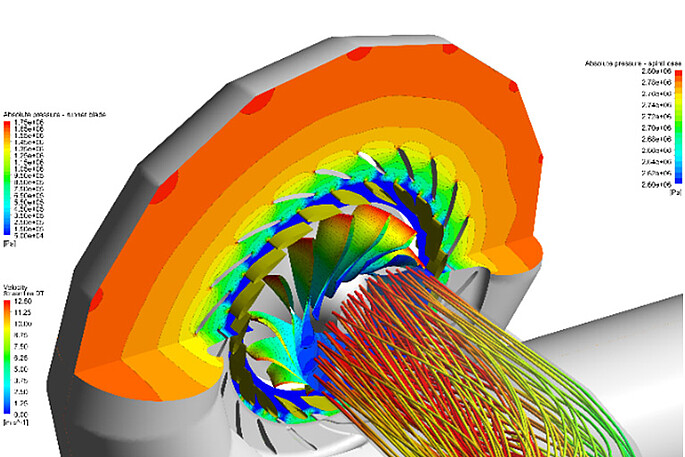

A CFD study of the original turbine configuration was initially carried out as the basis for the new development of the impeller, which had to be integrated into the existing guide vane and mounted on the existing draft tube. While most of the turbine components could be modelled based on existing drawings, the Francis impeller was scanned on-site, thus laying the foundation for the geometric reconstruction.

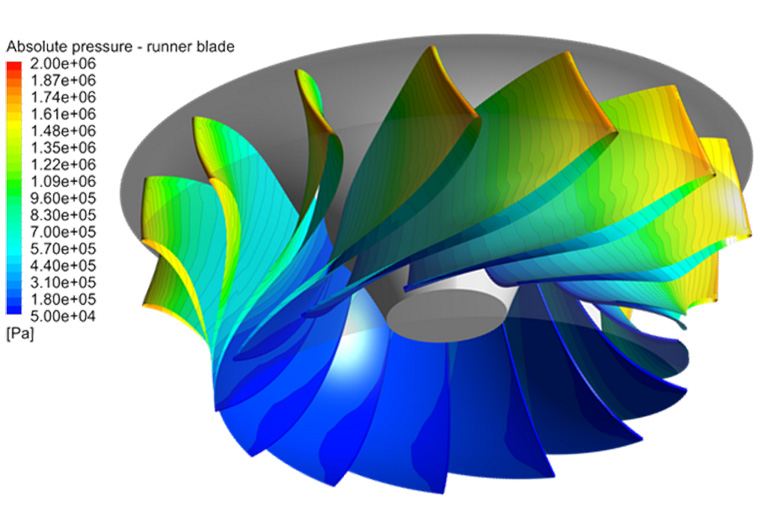

A new impeller design was developed step by step using suitable design tools and repeated CFD simulations with the aim of reducing the relative velocity in the blade channel in the area of the outer ring and simultaneously increasing the turbine efficiency. The following figure shows the CFD-calculated pressure distribution at the design point of the optimised impeller.

The new impeller design, which is provided with an HVOF WOC coating, is intended not only to extend the service life but also to increase the annual work of the system.

Subscribe and benefit

Stay informed about our

- conferences

- continuing education programmes

- activities