Investigation of the draft tube flow

on an existing system

We were commissioned by a leading turbine manufacturer to analyse the draft tube flow at an existing hydropower plant in Hungary using computational fluid dynamics (CFD).

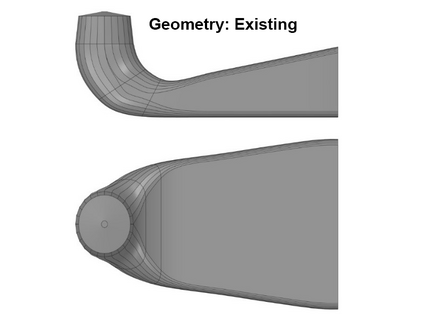

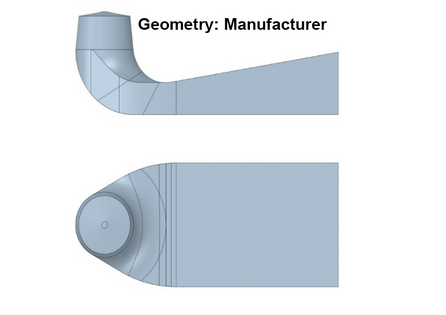

As part of a refurbishment project, a decades-old Kaplan turbine has to be replaced by a new one. As both the spiral and the draft tube must remain basically unchanged, it was necessary to check whether the new, model-tested hydraulic design of the guide vane and runner could be combined with the existing components without any significant loss in efficiency. In detail, it had to be clarified whether the performance would be unfavourably influenced by the existing draft tube.

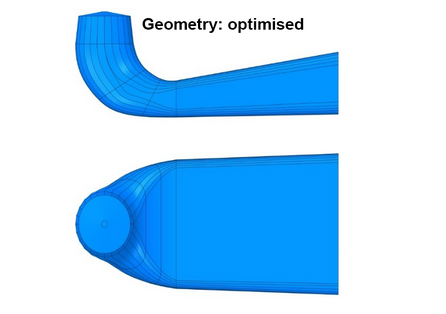

In this case, it was mandatory to extend the flow area to be investigated to include the guide vane, runner, draft tube and underwater area in order to be able to analyse the interaction of the individual components, and in particular the runner-draft tube interaction.

In addition to the existing draft tube geometry, a design proposed by the manufacturer and a draft tube version optimised by Jaberg und Partner were analysed. In the end, a technically and economically optimised solution was found for the end customer in close collaboration with the client.

Subscribe and benefit

Stay informed about our

- conferences

- continuing education programmes

- activities