Best Practice – On-Site Measurement

Flow rate measurement according to IEC 60041 - by means of impeller anemometer

The Meitingen power plant is the third one in the Lech Canal in the district of Augsburg in Bavaria, along with the Langweid and Gersthofen power plants. It was commissioned in 1922. Three horizontal Camel back turbines with a nominal flow of 42 m³/s each are in operation in the power house.

At this Meitingen power plant of Bayerische Elektrizitätswerke, the primary flow rate measurement according to IEC 60041 was carried out using an OTT C31 impeller anemometer before and after a runner renewal. The measurement were completed with a full estimation of the turbine efficiencies.

The Measurement Setup

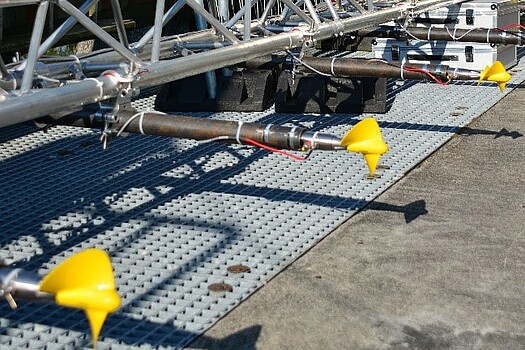

The calculation of the forces on the suspension of the measuring blades in the lowest area resulted in a load of 551 N. Due to this, the six OTT measurement rotors were mounted on a vertical 3-point traverse. After the preparation of the OTT rotors, the level probe was installed in the tailwater.

The signals from the instrumentation and control system were recorded by a power meter and fed into the measuring system. The rotor anemometers were moved horizontally with millimetre precision by the rake cleaner, brought into the respective measuring positions and a stationary flow was waited for. The evaluation of the determined flow rates was made in strict accordance with the standard, and an additional check was made with the aid of a 3D CFD system.

The measurement campaign itself was performed at machine no. 3 with guide vane positions that were changed in 5-degree increments - from 40 % to 100 %. To prove the reproducibility of the measured values, the guide vane positions 80 % and 90 % were repeated and the measured values were recorded.

For a representative measurement, 12 operating points plus two reproducibility measurements (80%, 90%) were carried out.

You might also be interested in this:

Best Practice - Field Measurement

Acoustic flow measurement

Plant Measurement acc. to IEC

Our measuring methods

Stay up to date

Subscribe to our newsletter and stay up to date on our activities, continuing education and conferences.

We are your independent expert for:

- On-site measurements according to IEC 60041 and IEC 62006

- Acceptance tests and model tests according to IEC 60193, ISO 9906, IEC 60534, IEC 62006

- Plant, operation and life cycle tests

- Endurance test

- Comparison of experimental data with numerical simulation (3D-CFD)

- Analysis, design and optimisation of hydraulic machines, components and complete systems

- Water hammer and pressure surge as well as transient conditions of fluid and gas flows

- Fluid-structure interaction

We look forward to your enquiry!

Our experts for on-site measurement acc. to IEC:

Jürgen Schiffer-Rosenberger

Dipl.-Ing. Dr.techn.

CEO and and Managing Partner

Stefan Höller

Dipl.-Ing.

Chief Engineer

Christian Bodner

Dipl.-Ing.

Chief Engineer